Concrete Pump Hose Safety: Best Practices for Every Job Site

Concrete Pump Hose Safety: Best Practices for Every Job Site

Concrete pumping is pivotal in modern construction, allowing for the efficient transport of concrete to various locations. However, the use of concrete pump hoses comes with significant safety risks. By adhering to best practices, we can ensure a safer working environment for all personnel involved. This article delves into the crucial

Jun 10,2025

Concrete Pump Hose Safety: Best Practices for Every Job Site

Concrete pumping is pivotal in modern construction, allowing for the efficient transport of concrete to various locations. However, the use of concrete pump hoses comes with significant safety risks. By adhering to best practices, we can ensure a safer working environment for all personnel involved. This article delves into the crucial aspects of concrete pump hose safety, offering comprehensive insights that can help prevent accidents and promote effective work practices.

Table of Contents

1. Understanding Concrete Pump Hoses

2. Common Hazards Associated with Concrete Pump Hoses

3. Safety Standards and Regulations

4. Essential Best Practices for Concrete Pump Hose Safety

4.1 Regular Inspection and Maintenance

4.2 Proper Handling Techniques

4.3 Safe Setup and Operation

4.4 Personal Protective Equipment (PPE)

5. Training and Awareness Programs

6. Emergency Response Procedures

7. FAQs on Concrete Pump Hose Safety

8. Conclusion

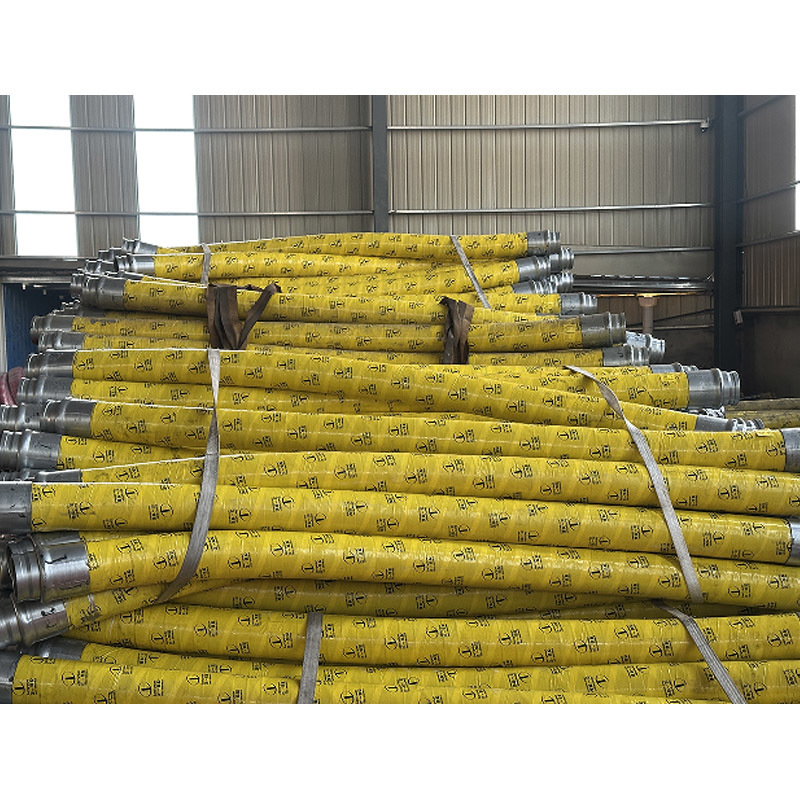

1. Understanding Concrete Pump Hoses

Concrete pump hoses are specialized components that facilitate the movement of liquid concrete from the pump to the desired pouring location. These hoses are designed to withstand high pressure and must be made of durable materials to ensure longevity and safety during operation. Understanding the functionality and limitations of these hoses is crucial for anyone involved in the concrete pumping process.

2. Common Hazards Associated with Concrete Pump Hoses

Various hazards are associated with concrete pump hoses, including:

- **Burst Hoses**: High pressure can cause hoses to burst, posing a danger to operators and nearby workers.

- **Whipping Hoses**: Improperly secured hoses may whip violently, leading to potential injuries.

- **Concrete Splashback**: If a hose becomes blocked or improperly positioned, concrete can splash back towards workers.

- **Tripping Hazards**: Hoses lying across walkways can create tripping hazards, increasing the risk of falls.

Recognizing these hazards is the first step towards implementing effective safety measures.

3. Safety Standards and Regulations

Safety standards governing the use of concrete pump hoses vary by region but are essential for maintaining a secure job site. Organizations such as OSHA (Occupational Safety and Health Administration) in the United States provide guidelines that outline the safe use of equipment. Familiarity with these regulations ensures compliance and promotes a safety-first culture among workers.

4. Essential Best Practices for Concrete Pump Hose Safety

To foster a safer working environment, we recommend the following best practices:

4.1 Regular Inspection and Maintenance

Conducting regular inspections of concrete pump hoses is vital. Check for signs of wear, cracks, or other damages before each use. Regular maintenance, including cleaning and pressure testing, can prevent accidents and extend the lifespan of the hoses.

4.2 Proper Handling Techniques

Employing proper handling techniques is crucial to prevent accidents. Always lift hoses using both hands and avoid dragging them across rough surfaces, which can cause abrasion and damage. When connecting hoses, ensure they are correctly aligned to prevent leaks and pressure loss.

4.3 Safe Setup and Operation

Setting up the pump and hoses correctly can minimize hazards. Ensure that the pump is stable and placed on a firm surface. Secure hoses with appropriate clamps and ensure they are positioned away from traffic areas to prevent tripping hazards. During operation, maintain a safe distance from the discharge area to avoid injury from potential burst hoses.

4.4 Personal Protective Equipment (PPE)

The use of Personal Protective Equipment (PPE) is essential when working with concrete pump hoses. Workers should wear hard hats, safety goggles, gloves, and steel-toed boots to protect against injuries. High-visibility clothing can also enhance safety on busy job sites.

5. Training and Awareness Programs

Training workers on concrete pump hose safety is vital. Comprehensive training programs should cover the proper use of hoses, hazard recognition, and emergency response procedures. Regular refresher courses can help maintain awareness and ensure workers remain informed about the latest safety practices.

6. Emergency Response Procedures

Developing and implementing emergency response procedures is crucial for handling potential accidents involving concrete pump hoses. Workers should be trained to understand these procedures, including how to respond to hose bursts, splashes, or injuries. Quick and effective responses can mitigate injuries and prevent further accidents.

7. FAQs on Concrete Pump Hose Safety

What are the signs that a concrete pump hose needs replacing?

Signs include visible wear, cracks, leaks, or significant discoloration. Regular inspection can help identify these issues early.

How often should concrete pump hoses be inspected?

Hoses should be inspected before each use, and a more thorough inspection should be conducted regularly as part of a maintenance schedule.

Can I use any hose for concrete pumping?

No, only hoses specifically designed for concrete pumping should be used, as they are engineered to withstand high pressure and abrasion.

What should I do if a concrete pump hose bursts?

Immediately stop the pump, evacuate the area, and report the incident to a supervisor. Follow the emergency response procedures established on-site.

Is training on concrete pump hose safety mandatory?

Yes, training on safety practices is essential to ensure all workers are aware of hazards and can operate equipment safely.

8. Conclusion

Concrete pump hose safety is a critical aspect of construction operations that cannot be overlooked. By understanding the hazards, adhering to safety standards, and implementing best practices, we can significantly reduce the risk of accidents. Regular training and awareness programs further enhance safety on job sites. Prioritizing these measures not only ensures the safety of all personnel involved but also contributes to the overall efficiency of construction projects. Remember, a safe job site is a productive job site.

Contact Us

E-mail:

sales@dongbopipe.com

Phone/WhatsApp:

+86-15031992089

Address:

Niu Jin Zhuang Xiang Bang Zhang Cun Nan, Mengcun HuiAutonomous County, Cangzhou City, Hebei Province, China